We recognise that as designers for interior and homeware emporiums it is important for you to match your printing needs to the brand or narrative. Once we have an exact understanding of your tastes, inspirations and desires we can suggest specific papers, finishes and print solutions to suit your requirements. In the same way that you may provide tailored design solutions for your clients, we’re confident working together we will create print work that exceeds your expectations.

Ex Why Zed are specialist creative interior and homeware booklet printers who will work with you to take your artwork from screen to a wide range of printed outcomes.

Size, number of pages and quantity are the factors that have the biggest impact on your price. Increasing or reducing these can stretch your budget.

There are almost infinite possibilities on size, finishing and papers. However, the three basic choices for paper finish are silk, gloss or uncoated. Your inside pages will be between 100 and 170gsm. For a thick cover choose 300gsm or 350gsm. The best thing to do is take a while to watch our video guides and look through our case study portfolio. We have listed the print spec of each book so if there is something that will work well for your publication, note down the spec and we can quote on like-for-like.

Ultimately, the factors you need to choose are:

• What size is your catalogue?

• How many pages do you have?

• What kind of finish would work best with your artwork: silk, gloss or uncoated?

• What type of binding? The rule of thumb is Wire Stitching (stapling) for up to 40 pages and Perfect Binding for over 40.

• And finally how many copies would you like?

We do want to help you print your promotional booklet for a fair price so here are some ways you can reduce the price per copy:

• The more copies you print, the lower the unit price will fall.

• Using house papers rather than premium, branded sheets.

• If you print all the pages onto the same paperweight (maybe 130-170gsm) rather than having a thicker cover that is only one print run for us.

• A4 portrait and A5 landscape are cheaper to print than A4 landscape.

• Reducing the number of pages.

• Reducing the weight of the cover and inside pages will help a little but it doesn’t have a big impact on the overall price.

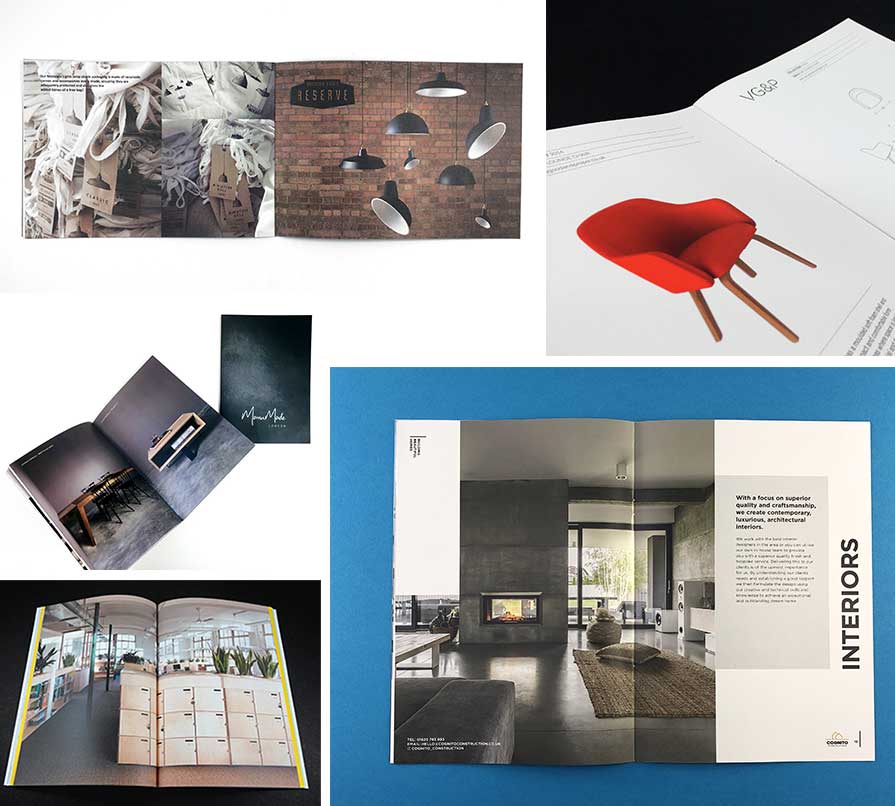

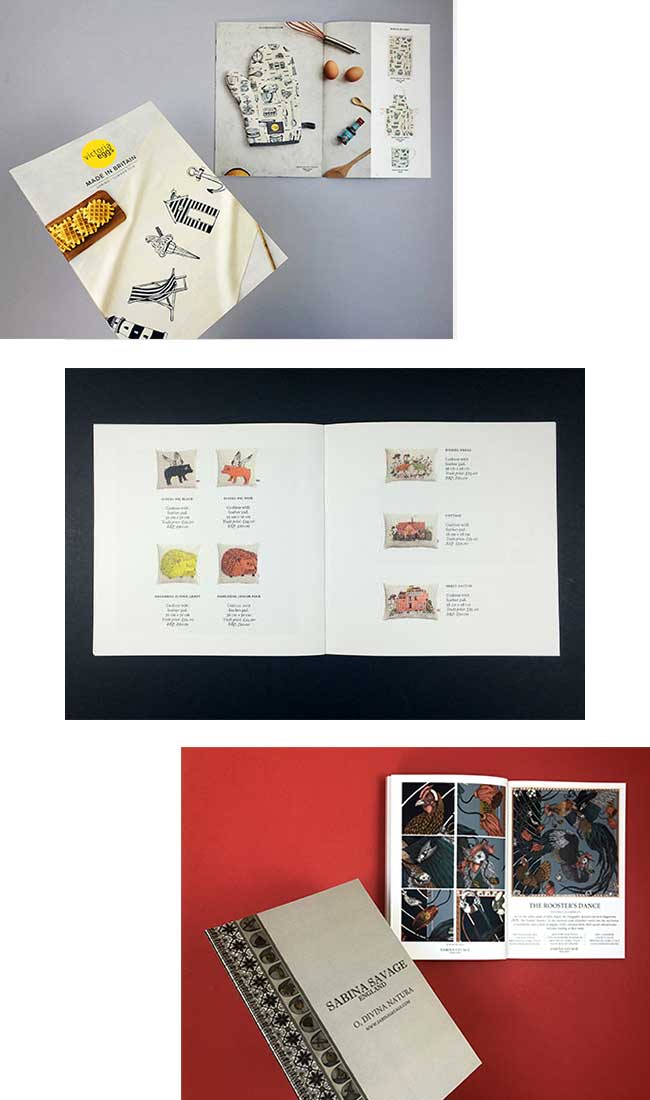

We have been doing this a while now and have seen a lot of impressive publications come off our presses. To give you a head start with your homeware booklet printing, here are three print specifications which work well (and photos of them, see right). Each has its own characteristics which have proven to be winning combinations from a production perspective, cost per unit and most importantly, have reader appeal.

If any of our showcase options would work for your project, take a note of the spec and jump on our quote form to receive your bespoke quotation. Or ping us an email on hello@exwhyzed.fixed-staging.co.uk if that is easier.

Showcase 1 – a cost-saving professional-looking stapled booklet which you can post out for one first-class stamp:

A5 Stapled Booklets.

24pp Self Cover onto 170gsm Silk.

(Self cover means all of the pages onto the same paper weight)

Full colour print throughout.

As a guide, you could print 250 copies of this for £254.

Showcase 2 – a compact square booklet with 32 pages to showcase your brand:

210x210mm Stapled Books

4pp Cover onto 300gsm Uncoated

Matt Lamination to outer

28pp Text onto 115gsm Uncoated

Four colour print throughout.

Showcase 3 – a stylish perfect bound with 40 pages of A5 content:

A5 Perfect Bound Books

4pp Cover onto 300gsm Silk

Matt Lamination to outer

36pp Text onto 130gsm Silk

Four colour print throughout

As a guide, you could print 100 copies of this for £2.36 per copy.

Tweaks you could consider:

• Reducing the cover to 250gsm which also makes it slightly easier to open.

• Choose uncoated for a tactile, rustic appearance. Your images will print more muted than they appear on screen.

• Or go for silk or gloss for a smooth, brighter aesthetic.

• Change between matt or gloss lamination for the cover.

• Increase the size to A4 for a more imposing booklet or if you have more content.

• Reduce to A6 for a neat book that is cheap to post out to your mailing list.

• Increase the weight of the inside pages to 170gsm making it more premium.

• Foil or Gloss Spot varnish some content on the cover for a luxury finish (this is an additional £280).

Enjoy looking through our showcase of recent homeware and interior printing

We have done our best to give you a huge wealth of information on this page and in our guides but if here are some frequently asked questions to help you get your work into print.

Ready to place an order? Brilliant, you’ll need to upload the files using www.wetransfer.com sending them to hello@exwhyzed.fixed-staging.co.uk and in the comments box let us know the number of copies you’re going for and the best address for delivery. We’ll then give your artwork a free preflight check to highlight any potential issues and will email with any advice or recommendations before going to production.

Once we receive your print ready artwork, we’ll aim to deliver in 5/6 working days (we do get busy at degree show time). If you are working to a crucial deadline PLEASE allow more time – there’s no harm in getting the artwork to us early so we can deliver a few days before the show starts 🙂

We will aim to deliver in 4/5 working days after we receive your print ready artwork. Allow a little longer if you got for bespoke papers, premium cover options and a longer print run (500 copies+).

Once we have checked your artwork we will send over an invoice for you to pay by online bank transfer or credit card through Stripe.

Lamination is a thin layer of protection which prevents the ink cracking. Win win. It comes in matt, gloss, soft-touch or anti-scuff.

Matt Lamination works best with silk and uncoated covers. We would suggest using gloss lamination if you are aiming for a super shiny, high impact cover. Soft-touch has a velvet, illustrious feel but does attract finger marks REALLY quickly so best not eat your lunch before reading!

The short answer: when paper is printed, the ink sits on the surface. When it is then folded to make your cover the ink can crack. While you should never judge a book by it’s cover, this cracking will look unprofessional. Lamination is a thin layer of protection which prevents the ink cracking. Win win. It comes in matt, gloss, soft-touch or anti-scuff.

https://www.youtube.com/embed/9elKD4qeGKU

https://www.exwhyzed.fixed-staging.co.uk/resources/setting-3mm-bleed-on-artwork-for-print/

We will need 3mm bleed on all the edges, you’ll notice at the moment that the artwork stops at the crop marks – it needs to extend 3mm beyond this to avoid any chance of a white border.

The following page includes illustrated and video guides on how to set up bleed correctly:

https://www.exwhyzed.fixed-staging.co.uk/resources/setting-3mm-bleed-on-artwork-for-print/

You might have set this up correctly in InDesign but when you export to PDF just make sure that in the ‘Marks and Bleeds’ menu you not only tick ‘Crop Marks’ but you also add ‘3mm’ in to the four bleed boxes – top, bottom, inside and outside. This will add the bleed to the exported PDF.

BLEED FIX

It’s one of two things:

Have you dragged the background image out 3mm beyond the black line on your Indesign file into the bleed area? Try that then export again.

OR you have done the above but then when you’re exporting you need to click the Marks and Bleeds menu, then type ‘3mm’ into the four bleed boxes. This will add the bleed to the pdf.

Yes we can and they all create a stunning additonal visual layer to wow your readers.

We can!

Have a good look through the many choices on their website

https://www.gfsmith.com/collection/

then request some paper samples direct on samples@gfmsith.com

Let us know what you would like and we’ll send over a bespoke quote.

The Ashley Hicks book shown above uses 250gsm GFSmith Gmund Bier and has gold foiling for an extra luxury edge.

We will need the cover of your book supplied as two spreads – the outer cover and the inner cover.

When you export to PDF can you set the bleed to 3mm on the right and left and 10mm on the top and bottom – this way the hairlines will show on the PDF and we’ll know where to fold the spine. We have locked the hairlines and white box so drop your artwork in over those.

The inside pages should be supplied as single pages NOT spreads. Just choose ‘Pages’ rather ‘Spreads’ when you export to PDF and that should sort it!

We don’t advertise our prices online because we prefer to open up a conversation with you and find out a little bit about the project. Your artwork is unique and bespoke, so in turn, we will provide you a unique and bespoke print quote for your job. I am sure you will take no fun in looking at a boring spreadsheet with rows of bemusing numbers so we don’t put you though that.

Wire stitching is a little bit of print jargon for ‘stapling’. If you have an A5 booklet then we print it onto A4 sheets, fold them in and put staples along the left-hand edge to bind the sheet together. In some quarters, this is also known as ‘saddle stitching’. Let’s stick with stapling though if that’s easier 🙂

Needs to be a multiple of four pages to work as a stapled booklet. Why? Because when you fold a printed sheet in half, you get four pages of content – try it there and you’ll see what we mean 🙂

The perfect bound method of binding will give your publication a square spine and professional looking finish.

For further advice follow our perfect binding set up guides.

Yes, ‘text’ pages is our common term for the inside pages of your publication. They can be filled with illustrations, photography, full colour artwork…or just text if it’s a poetry book.

For the purposes of our quoting, we call a page one side of content. So, a sheet of paper has two pages – a front and a back. If you ask for a quote for 40 inside pages, that will be 40 pages of content, 40 pages in your artwork file / pdf and in the book 20 leaves printed on both sides.